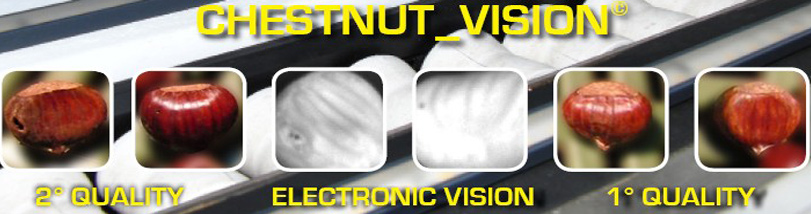

Chestnut Vision Unitec Technology is the new and innovative non-destructive system designed and built by Unitec for quality selection in chestnuts. The system detects any defects in chestnuts, in particular pest-damaged specimens, including those with only a tiny hole of half a millimetre in diameter and other blemishes on the skin.

The main characteristics of Chestnut Vision Unitec Technology are:

- an optical inspection system: it consists of multiple defect-detection tools and comprises a series of cameras that focus on the same fruit at various stages;

- a transport system designed specifically for chestnuts: it ensures complete rotation of the chestnuts during the optical inspection process. Special rollers guarantee proper rotation of these highly irregular-shaped products, which vary considerably in shape from one fruit to another;

- an innovative lighting system, specifically designed for this product, enables detection of any tiny holes in the chestnuts which constitute the entry point of the worm or pest. This very difficult project entailed years of work, also because some varieties of chestnut have black skin which actually resembles the holes themselves.

What results have we achieved with this type of technology? This technology is an important and strategic breakthrough in chestnut processing because it allows automatic, safe, rapid and reliable chestnut selection, without the use of manual labour.

Present-day manual selection of this fruit, carried out by processing plant workers, is an alienating, laborious and stressful task which never yields entirely satisfactory results. Indeed, in order to ensure good selection, processing plants that rely on manual selection of chestnuts have to resort to three product selection stages, using three different groups of workers who remove the defective fruits at each successive stage, since the defects are difficult to spot. This technology enables accurate inspection and identification of defects in pest-damaged chestnuts.

The use of Chestnut Vision Unitec Technology can also be extended to ready-peeled chestnuts destined for the food industry, used for the production of marron glacés.

This innovative technology developed by Unitec is now at the service of the market and its clients (having been tried and tested at a processing plant in Italy) and will make it possible to increase processing efficiency by reducing chestnut processing costs and improving the quality of produce presented to the market.